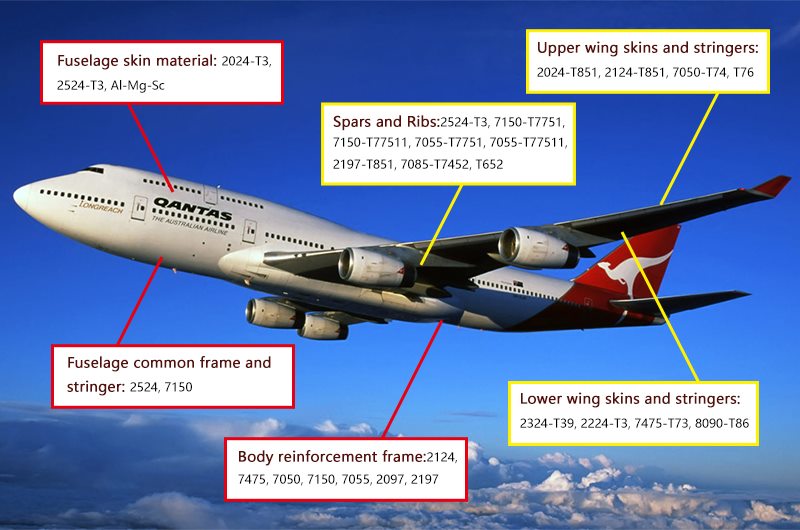

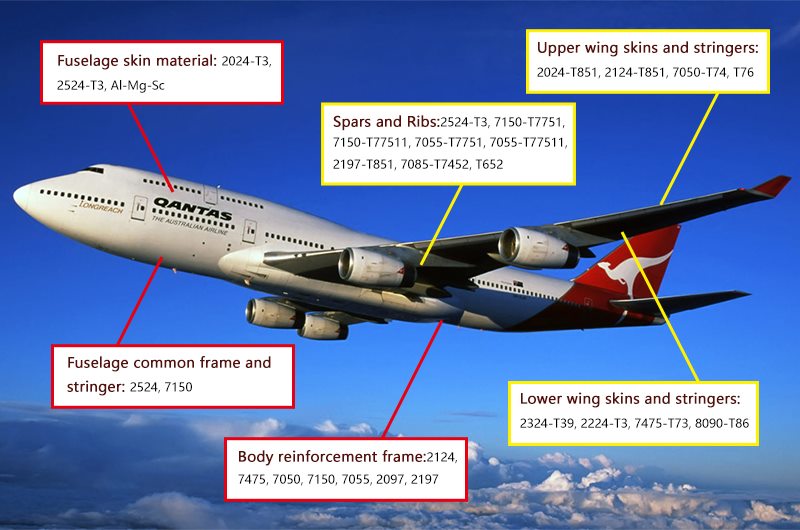

Conveyor generally requires long service life, high reliability, low maintenance and use cost. Aluminum alloy has the advantages of low density, excellent comprehensive performance, mature application in aircraft and low cost. Therefore, its consumption in transport aircraft is generally more than 70%. In 1935, the world's first commercial aircraft DC-3 was successfully applied, and its main structural materials were mainly 2024-T3 alloy, which was very advanced at that time. The progress of aluminum alloy material technology is inseparable from the demand and development of transport aircraft. Aluminum alloy manufacturers in the world often cooperate with large aircraft manufacturers to improve and modify aluminum alloy materials and develop new materials. For example, Alcoa and Boeing have jointly developed 2324, 7150, 2524 7055 and a series of aluminum alloy materials with excellent performance, and these materials can be quickly applied to aircraft.

Requirements of conveyor for the development of aluminum alloy

1 fuselage

At present, the fuselage structure adopted by the transport aircraft is semi hard shell type, and the stress of each part: the skin bears the cabin load and shear force, the stringer or longitudinal beam bears the longitudinal tensile and compressive load, the ordinary frame supports the skin shape and distributes the skin load, and the reinforced spacer frame bears the concentrated load. In the material selection of fuselage design, strength, modulus, fatigue crack growth rate, fracture toughness and corrosion resistance are all important factors to be considered. However, according to the different structures and positions of various components in the fuselage, they have different requirements for key performance in material selection.

(1) fuselage skin material. The fuselage skin has high requirements for fracture toughness and fatigue crack growth rate. The commonly used alloy is 2024-T3 thin plate. Since 2024-T3 aluminum clad sheet was applied in DC-3 transport aircraft, it has almost become the standard material for aircraft fuselage skin, but in the late 1980s, 2 ××× After continuous modification and improvement, 2524-t3 aluminum alloy sheet has been successfully developed and successfully used as the fuselage skin of B777. Design of aluminum alloy fuselage skin

The disadvantage is not its low static characteristics, but its low durability and damage tolerance. In fact, the static characteristics of the newly developed skin alloy 2524 are similar to those of 2024, except that 2524 has high fracture toughness and strong crack growth resistance, which shows that the use of 2524 alloy can save structural weight or prolong service life. The bending capacity of 2524-t3 alloy is better than that of 2024-T3 alloy. Using 2524-t3 aluminum alloy can save the manufacturing cost of parts because it does not require additional heat treatment.

In addition, as an important alternative material for fuselage skin, Al Mg SC alloy is also a research hotspot in recent years. The strength of traditional Al Mg alloys can be improved by deformation strengthening, but the plasticity and toughness of the alloy are reduced at the same time; The plastic toughness of the alloy can be restored to a certain extent by heat treatment, but the strength is reduced. The addition of al3sc can strengthen the precipitation of two elements into the alloy, and al3sc can improve the strength of the alloy; Then, the precipitated al3sc particles pinned the dislocation, which improved the plastic toughness of the deformation strengthened alloy in the subsequent heat treatment process, but the strength decreased little.

The fracture toughness and crack propagation resistance of Al Mg SC alloy sheet are equivalent to those of 2524 alloy, and the corrosion resistance and welding performance are equivalent to those of Al Mg alloy. To sum up, fuselage skin materials pursue higher fracture toughness, crack propagation resistance and good corrosion resistance. At present, the optional materials mainly include 2024-T3, 2524-t3 and Al Mg SC alloy sheet.

(2) Fuselage ordinary frame and stringer. Generally speaking, the stress of the ordinary frame and stringer of the fuselage is small, and the main function is to support the shape and transmission

Load transfer. 7075-t62 alloy sheet is usually used for fuselage frame material, and 2024-T3 and 7075-T6 alloy sheet or extrusion can be used for stringer. In the past, these materials used in fuselage frame are prone to machining cracks and are sensitive to stress corrosion fracture. Using 7150-t77 alloy sheet and extrusion to manufacture fuselage frame and stringer has gradually become the main option of advanced aircraft. The extrusion of 7150-t77 alloy is used as the fuselage stringer, its strength is higher than that of 7075-T6 alloy, and its durability and damage tolerance exceed or at least equal to that of 7075-t76 alloy. If 7150-t77 alloy sheet is used as

When the frame and stringer materials are used in combination with 2524-t3, a new skin alloy, the improvement of the strength of the frame and stringer can increase the bearing strength of the members. The combination of 2524-t3 alloy skin and 7150-t77 alloy frame and stringer can obtain 17% weight reduction effect, which is equivalent to the 25% weight reduction effect of graphite composite, but the cost is low and the risk is small.

At present, the application research of 7055-o alloy sheet is being carried out in the United States. When 7055-o alloy sheet is used to manufacture fuselage frame, its formability is good. If it is treated into T77 state, it can obtain higher strength, fracture toughness and stress corrosion resistance better than 7075-T6 alloy. For the optional materials of fuselage ordinary frame and stringer, the transition from 2024 and 7075 alloy to 2524 and 7150 alloy is mainly carried out, and the application research of 7055 alloy is under way.

(3) Fuselage reinforced spacer frame. The fuselage reinforced spacer frame is the most important load-bearing component on the fuselage, and the fuselage spacer frame is required by high-level cyclic load

The material has high strength, stiffness, good durability and damage tolerance. Reinforced spacer frames are usually machined from thick plates or forgings. At present, 2124, 7475 and 7050 alloys are mainly used for the fuselage reinforced spacer frame.

After the emergence of 7150 and 7055 alloys, European and American countries began to gradually adopt them to manufacture fuselage partition frames. Aluminum lithium alloy has lower density and higher elastic modulus than traditional aluminum alloy. At present, the application research of aluminum lithium alloy in fuselage partition frame is actively carried out. Development goals of fuselage frame materials: ① the strength and toughness are at least equivalent to that of 2124-t8 alloy; ② Toughness is basically not lost in medium and high temperature environment; ③ Good spalling corrosion resistance, and the short transverse stress corrosion resistance is better under the stress of about 172 nmm2; ④ The anisotropy of the material is acceptable; ⑤ The crack propagation resistance of the material is high.

The aluminum alloy materials that can be used for the fuselage partition frame mainly include 2124, 7475, 7050, 7150, 7055, 2097, 2197 and other alloys.

2 wing

The wing generally adopts wing box structure, and the wing box bearing air pressure is composed of upper and lower wing surfaces, stringers and stiffeners. The wing transmits all the air pressure load to the joint with the fuselage through the beam. The upper wing skin and stringer of the wing mainly bear compression load. Therefore, the compression yield strength and modulus are the key factors to be considered in the design and material selection. The lower wing mainly bears tensile load, so tensile strength, tensile yield strength and modulus are the main static performance indexes affecting material selection, but for the lower wing structure, fatigue performance and fracture toughness are the most important. The upper and lower wing surfaces also bear bending and torsional loads. The material selection of the upper wing beam is the same as that of the upper wing surface, and the material selection requirements of the lower wing beam are the same as those of the lower wing surface. Static strength performance is the most important factor to be considered in the design of stiffener materials, such as tensile strength, compressive yield strength and modulus.

(1) upper wing skin and stringer. The original upper wing was riveted by thin plates and stringers, and the peak aging T6 state of 7 was successfully adopted ××× As the structural material of the upper wing, aluminum alloy has low spalling corrosion resistance and poor stress corrosion resistance in short transverse direction, but these problems have been solved through anti-corrosion treatment and the use of plates with a thickness of less than 50 mm. However, after the 1970s, thick plate integral machining parts began to replace the previous riveting structure. Commonly used materials include 2024-t851, 2124-t851, 7050-t74, T76 and other alloys. In the late 1980s, aircraft design began to adopt damage tolerance design and reliability design, which required materials with high strength and fracture toughness

Excellent corrosion resistance and stress resistance. Therefore, higher requirements are put forward for the previously used 7050 Alloy. Therefore, Alcoa company developed 7150-t77 thick plate and extrusion and applied it to C-17 conveyor for the first time. The alloy meets the design requirements of the wing upper wall panel and obtains a good weight reduction effect. Subsequently, Al COA developed 7055-t77 thick plate and extrusion, which were successfully applied to B777 aircraft and achieved good application results.

(2) Lower wing skin and stringer. The lower wing skin and stringer are similar to the upper wing structure, but bear different loads. At first, 2024-T3 alloy is often selected as the general material of lower wing skin and stringer. Since b757767, Boeing has used 2324-t39 alloy thick plate and 2224-t3 alloy extrusion as lower wing surface materials, because their strength is higher than that of 2024 alloy, which can achieve better weight reduction effect. 7475-t73 alloy has been widely used in high-performance military transport aircraft because of its excellent combination of strength and fracture toughness. Due to the low density of 8090 alloy and great weight reduction effect, 8090-t86 alloy plate and extrusion are being considered to be applied to the wing structure of large transport aircraft. In order to reduce the manufacturing cost of wing, the research on aging forming technology of wing is being carried out to tap the cost saving potential of aluminum alloy.

(3) wing beam and rib. The wing beam is an important load-bearing member, which was initially made of 7075 and 2024 alloys. At present, Airbus mainly uses 7050-t76 and 7010-t76 alloy thick plates to process wing beams. Boeing chose 7150-t77 alloy to make spar on B777. However, on the A380 aircraft, Airbus chose the new aluminum alloy 7085 to manufacture the wing beam and wing rib. At present, high-purity alloys are mainly used in aircraft that have been mass produced, including 2124-t851, 2324-t39, 2224-t3511, 7475-t73, 7475-t76, 7050-T7451, 7050-t7452, 7010-t74 and 7150-t61; On the most advanced aircraft developed since the 1990s, the newly developed 2524-t3, 7150-t7751, 7150 - t77511, 7055-t7751, 7055-t77511, 2197-t851, 7085-t7452 and t652 are used.

The application of aluminum alloy in the body of transport aircraft has a long history and large consumption, which has always occupied a dominant position. The development of aluminum alloy must continuously improve the performance of materials and develop new alloys according to the design requirements of conveyor. At present, China's main civil airliners all rely on imports, and the transport capacity of military transport aircraft is obviously insufficient. In order to develop China's large transport aircraft, we should speed up the research and application of high-performance, high damage tolerance and low-cost aluminum alloy, strengthen the technical level of China's aluminum alloy industrial equipment, and create conditions for the research and development of large transport aircraft。